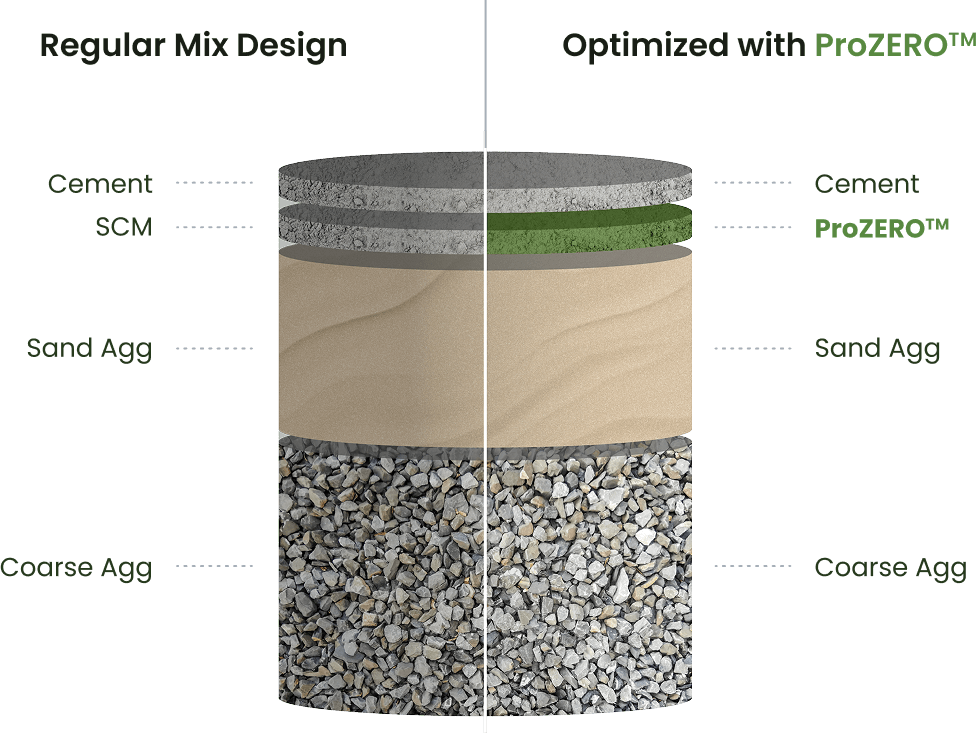

Ready Mix Optimized by ProZERO™

Carbon Negative OR Low Embodied Carbon Cement. ProZERO™ replaces cement in any mix design.

The more cement you replace, the lower your carbon. Collaborate with Prometheus professionals to design a custom mix that meets your low embodied carbon goals.

- Substitutes cement in a 1:1 ratio

- Finishability - Superior

- Rheology - Improved

- ASTM C1157

- ASTM C595 Type 1C

Break History

7 Day – 3,274 PSI

14 Day – 4,206 PSI

28 Day – 4,593 PSI

How you can work with it

Example Mix Optimized with ProZERO™

Other Applications

Available in Flowable Fill

Flowable fill is a specific type of ready mix that is quicker to place and finish. This is perfect for backfill, structural fill, trenches, storage tanks, etc.

ProZERO™ optimized flowable fill maintains comparable slump, and removability modulus.

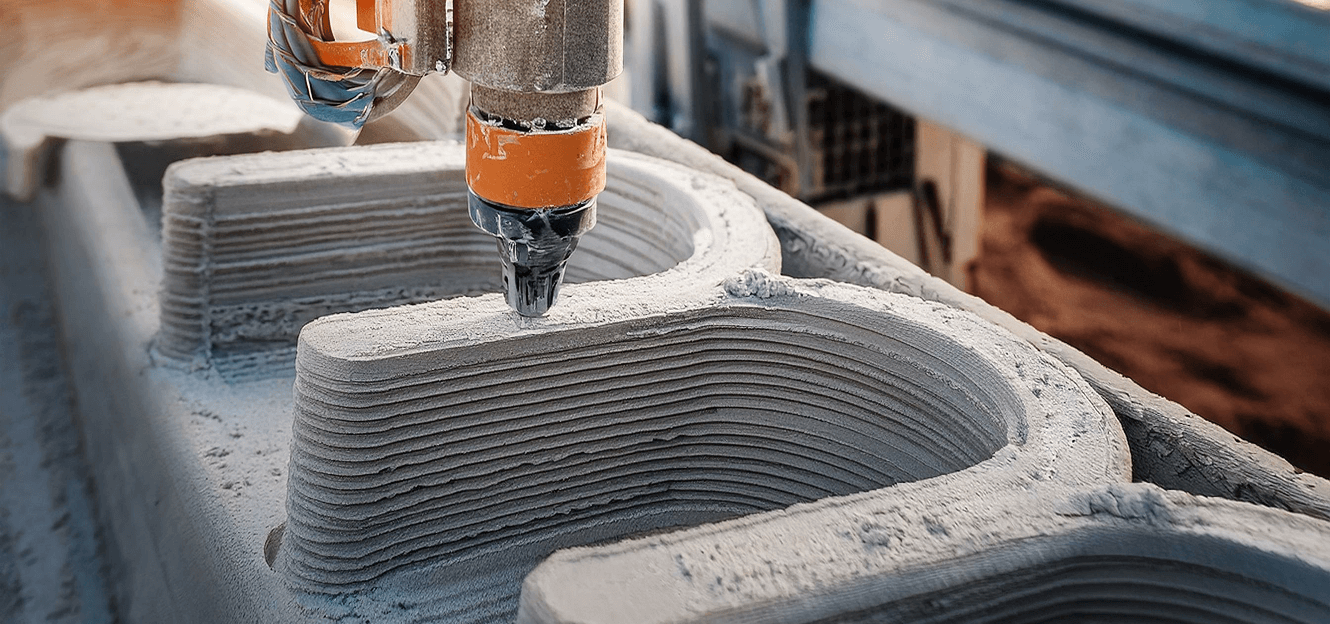

3D Printing

The way of efficiency and the future Prometheus is partnered with AutoDesk to develop a ProZERO™ optimized feedstock for efficient 3D Printing.

- In Development - 2026

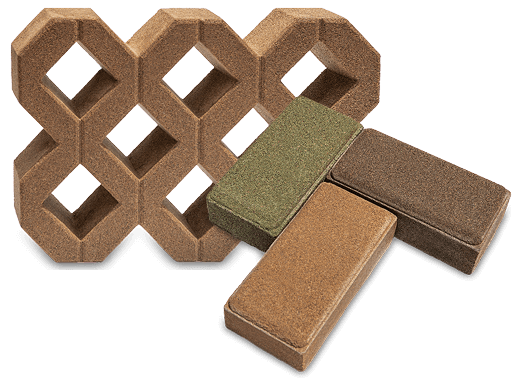

Manufactured Goods

ProZERO™ Carbon Negative blocks

Eliminate ~100% of the embodied carbon found in traditional cement-based CMU’s.

- ASTM C90

- ASTM C129

- ASTM E84

Constructability

•Coating: Accepts acrylic based and potassium silicate coatings

• Flashing: Achieves traditional flashing component performance– plus, NO pre-drilling required for tapcons / termination bar

•Fastening: Attains conventional fastener performance

– plus, NO pre-drilling required for self-tapping screws

Technical Data

Compressive Strength – 2,400 – 3,500 PSI

Flexural Strength – 800 – 1,200 PSI

Density – 104- 108 pcf.

Absorption – 13- 18 pcf.

NRC – 0.10

Noise Reduction Coefficient

FSI & SDI – Class A

FSI – 0-25

Flame Spread Index

SDI- 450 max

Smoke Development Index

Dimensions

8″ Width

8″ Height

8″ Length

Other Applications

Pedestrian & Parking Surfaces

Low Carbon Paving Solutions

A sustainable and durable parking, pedestrian & stormwater management solution

- In production

Hardscape Wall Systems

Segmented Wall Unit Solution

Sustainability plus sound absorption for residential, roadside and other environments

- In development

Sound Attenuation

Acoustic Panel Solution

Superior strength & sound absorption in thinner, lighter panels that are zero-carbon

- In testing